Who is going the extra mile at work?

Most every industry has a version of a safety walk-through. But when the tone of the walk-through resembles a military inspection, the purpose of promoting safe work practices can be lost. Employees often resent the “gotcha” approach to infractions, instead of helpful suggestions to improve safety.

Part of the job is for everyone to be on the lookout for potential errors, but everyone should also take notice when they see best practices at work. Safety reports should include what the crew is doing right, along with how they can improve.

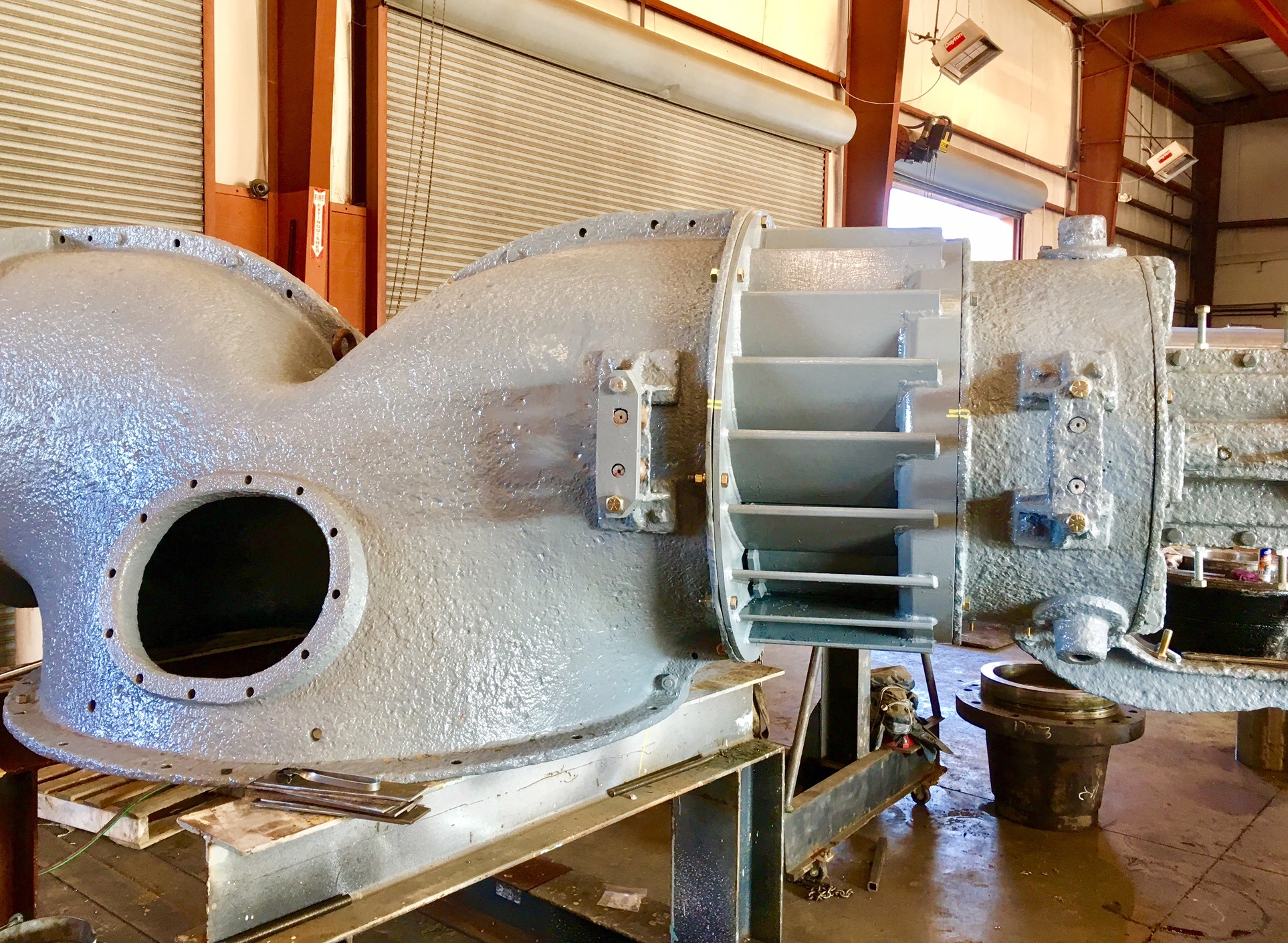

This photograph tells a great story. This crane operator is cleaning a stain on the floor of the powerhouse (with a scrub brush) during a break in his crane operating duties. No one asked him to clean up this spot. It needed attention, so he attended to it. This crane operator’s action needs to be the main focus of the next safety meeting. He exemplifies a best practice at work – let’s say thank you.

I once attended a safety meeting where there were twelve people in the room. The topic of conversation was safety glasses, one of the most important pieces of PPE on a job site. But the specifics of the safety violation made me wonder if we were missing the point. At the end of the day, a millwright was exiting the building. A safety manager wrote up a citation because the employee removed his safety glasses as he walked to his vehicle. There was no signage requiring PPE in job site parking lot, and no other crew members were familiar with this rule. Can you imagine how that employee felt about safety at that moment?

There is no question that a safety walk-through needs to uncover unsafe and potentially unsafe working conditions. If we foster a good working relationship between the employees and the safety professionals, then the employees will point out their concerns and even suggest the best corrective actions. We all need to be on the same side when it comes to safety. And we need to thank the crane operators and the other pro-active employees on our job sites for a job well done!

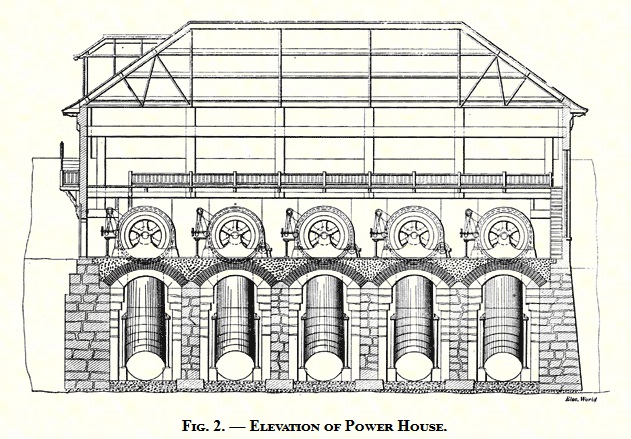

Hydropower was the first large-scale renewable energy source used in the US. Many of the hydro sites where RUS works today are well over 100 years old. While we all count on the reliability of hydropower, it is easy to forget how revolutionary the idea was in 1895 to transmit generated hydropower over cable lines to homes and businesses.

Hydropower was the first large-scale renewable energy source used in the US. Many of the hydro sites where RUS works today are well over 100 years old. While we all count on the reliability of hydropower, it is easy to forget how revolutionary the idea was in 1895 to transmit generated hydropower over cable lines to homes and businesses.