Do it without thinking.

From our Safety Manager, Susan Dunlap.

From our Safety Manager, Susan Dunlap.

I received this text at 4:11 am on Sunday morning: “Thank you for teaching me.”

Usually a middle-of-the-night text means bad news. But this story has a happy ending. The RUS supervisor who texted me was referring to a Red Cross CPR/First Aid class that he took at our home office on December 26, 2018. On Saturday, January 11, he used what he had learned to perform CPR on his 21-year-old nephew.

“He didn’t have a pulse,” the supervisor wrote to me. “I drug him out of the chair and started compressions and blowing air in him. I didn’t count or anything. I just did it without thinking.”

Thanks to the employee’s quick response, his nephew’s pulse resumed before emergency personnel arrived on the scene. “I was going to stay up here this weekend (on the job site),” the supervisor said. “But I think God sent me home instead.”

To this employee, I want to express my sincerest appreciation:

- Thank you for paying attention in CPR class.

- Thank you for remembering what you learned.

- Thank you for taking action in an extremely stressful situation.

This simple text sums up why I love my job. Let us all take the skills we learn in workplace safety training home to our families, each and every day. We want to be ready when our loved ones need us the most. And in the words of the RUS supervisor, do it without thinking.

Our power generation maintenance crews often have to work on remote job sites. For some locations, there might not even be a hotel or restaurant for miles. Here are some tips on how our crews make the most of their time on the road:

Our power generation maintenance crews often have to work on remote job sites. For some locations, there might not even be a hotel or restaurant for miles. Here are some tips on how our crews make the most of their time on the road:

One of our hydro mechanics recently came across a banded water snake (also known as a Southern water snake). The mechanic opened the draft tube door to inspect the parking ledge for the runner – and realized he had some company in there. At RUS, we have a specific training module on snakes that is a required part of our new hire orientation. Making employees familiar with the types of snakes that are common to our work area, and teaching the crew what to do when they come across a snake, can keep a run-in from becoming a recordable.

One of our hydro mechanics recently came across a banded water snake (also known as a Southern water snake). The mechanic opened the draft tube door to inspect the parking ledge for the runner – and realized he had some company in there. At RUS, we have a specific training module on snakes that is a required part of our new hire orientation. Making employees familiar with the types of snakes that are common to our work area, and teaching the crew what to do when they come across a snake, can keep a run-in from becoming a recordable.

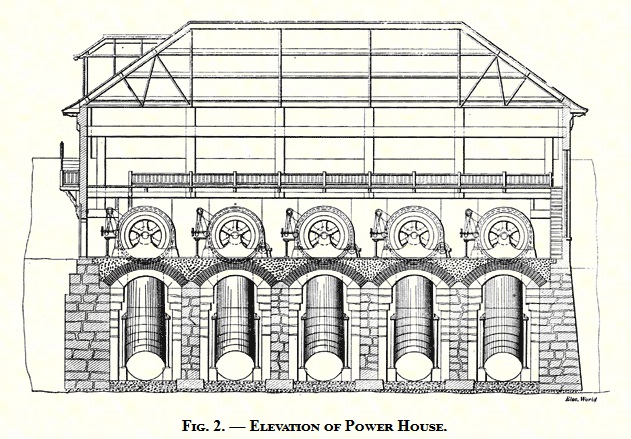

Hydropower was the first large-scale renewable energy source used in the US. Many of the hydro sites where RUS works today are well over 100 years old. While we all count on the reliability of hydropower, it is easy to forget how revolutionary the idea was in 1895 to transmit generated hydropower over cable lines to homes and businesses.

Hydropower was the first large-scale renewable energy source used in the US. Many of the hydro sites where RUS works today are well over 100 years old. While we all count on the reliability of hydropower, it is easy to forget how revolutionary the idea was in 1895 to transmit generated hydropower over cable lines to homes and businesses.

RUS is pleased to support Trees Coalition, a local non-profit dedicated to removing invasive species that damage trees (like kudzu, wisteria and English ivy). Danny Elder, RUS shop manager, repaired two important pieces of donated equipment for the TC work crew. Danny is pictured here with volunteer Dr. Bob Reynolds and Trees Coalition supervisor Anthony Radziewicz, along with a newly refurbished wood chipper and bush mower.

RUS is pleased to support Trees Coalition, a local non-profit dedicated to removing invasive species that damage trees (like kudzu, wisteria and English ivy). Danny Elder, RUS shop manager, repaired two important pieces of donated equipment for the TC work crew. Danny is pictured here with volunteer Dr. Bob Reynolds and Trees Coalition supervisor Anthony Radziewicz, along with a newly refurbished wood chipper and bush mower.

Power generation companies often need to get their mills back up and running as quickly as possible, without the added complication of waiting for back-ordered equipment. Keeping spare replacement parts on hand is not always feasible, and unscheduled purchases of new equipment can take a real hit to a capital expenditure budget. It might be time for your company to consider rebuilt equipment as an efficient and affordable option. Call RUS today to see how we can help you. Click below to view the latest brochure on our journal rebuild program.

Power generation companies often need to get their mills back up and running as quickly as possible, without the added complication of waiting for back-ordered equipment. Keeping spare replacement parts on hand is not always feasible, and unscheduled purchases of new equipment can take a real hit to a capital expenditure budget. It might be time for your company to consider rebuilt equipment as an efficient and affordable option. Call RUS today to see how we can help you. Click below to view the latest brochure on our journal rebuild program.