Living and Working on the Road

Our power generation maintenance crews often have to work on remote job sites. For some locations, there might not even be a hotel or restaurant for miles. Here are some tips on how our crews make the most of their time on the road:

Our power generation maintenance crews often have to work on remote job sites. For some locations, there might not even be a hotel or restaurant for miles. Here are some tips on how our crews make the most of their time on the road:

- Explore alternate accommodations. Trying to live off (and not exceed) the per diem allowance can be a challenge, but there is nothing more depressing than a cheap motel. A number of our crew members purchase campers and park them at local camp grounds. They make up for the cramped kitchens by grilling out as often as possible.

- Bring your own pillow. Even after a full day’s work, it can be difficult to sleep in unfamiliar surroundings – it feels like restful sleep is almost impossible to achieve. Invest in yourself and buy a top-of-the-line pillow – it makes a difference.

- Recharge during your free time. Working away from home gives you time to do the things that might otherwise seem like a luxury. In other words, make the most of your surroundings and go fishing every chance you get!

Being away from home and family during the week can be stressful. RUS appreciates the sacrifices that our crews make to get the job done.

One of our hydro mechanics recently came across a banded water snake (also known as a Southern water snake). The mechanic opened the draft tube door to inspect the parking ledge for the runner – and realized he had some company in there. At RUS, we have a specific training module on snakes that is a required part of our new hire orientation. Making employees familiar with the types of snakes that are common to our work area, and teaching the crew what to do when they come across a snake, can keep a run-in from becoming a recordable.

One of our hydro mechanics recently came across a banded water snake (also known as a Southern water snake). The mechanic opened the draft tube door to inspect the parking ledge for the runner – and realized he had some company in there. At RUS, we have a specific training module on snakes that is a required part of our new hire orientation. Making employees familiar with the types of snakes that are common to our work area, and teaching the crew what to do when they come across a snake, can keep a run-in from becoming a recordable.

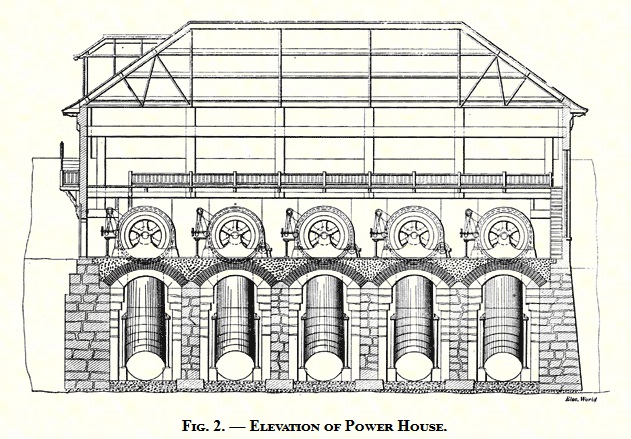

Hydropower was the first large-scale renewable energy source used in the US. Many of the hydro sites where RUS works today are well over 100 years old. While we all count on the reliability of hydropower, it is easy to forget how revolutionary the idea was in 1895 to transmit generated hydropower over cable lines to homes and businesses.

Hydropower was the first large-scale renewable energy source used in the US. Many of the hydro sites where RUS works today are well over 100 years old. While we all count on the reliability of hydropower, it is easy to forget how revolutionary the idea was in 1895 to transmit generated hydropower over cable lines to homes and businesses.

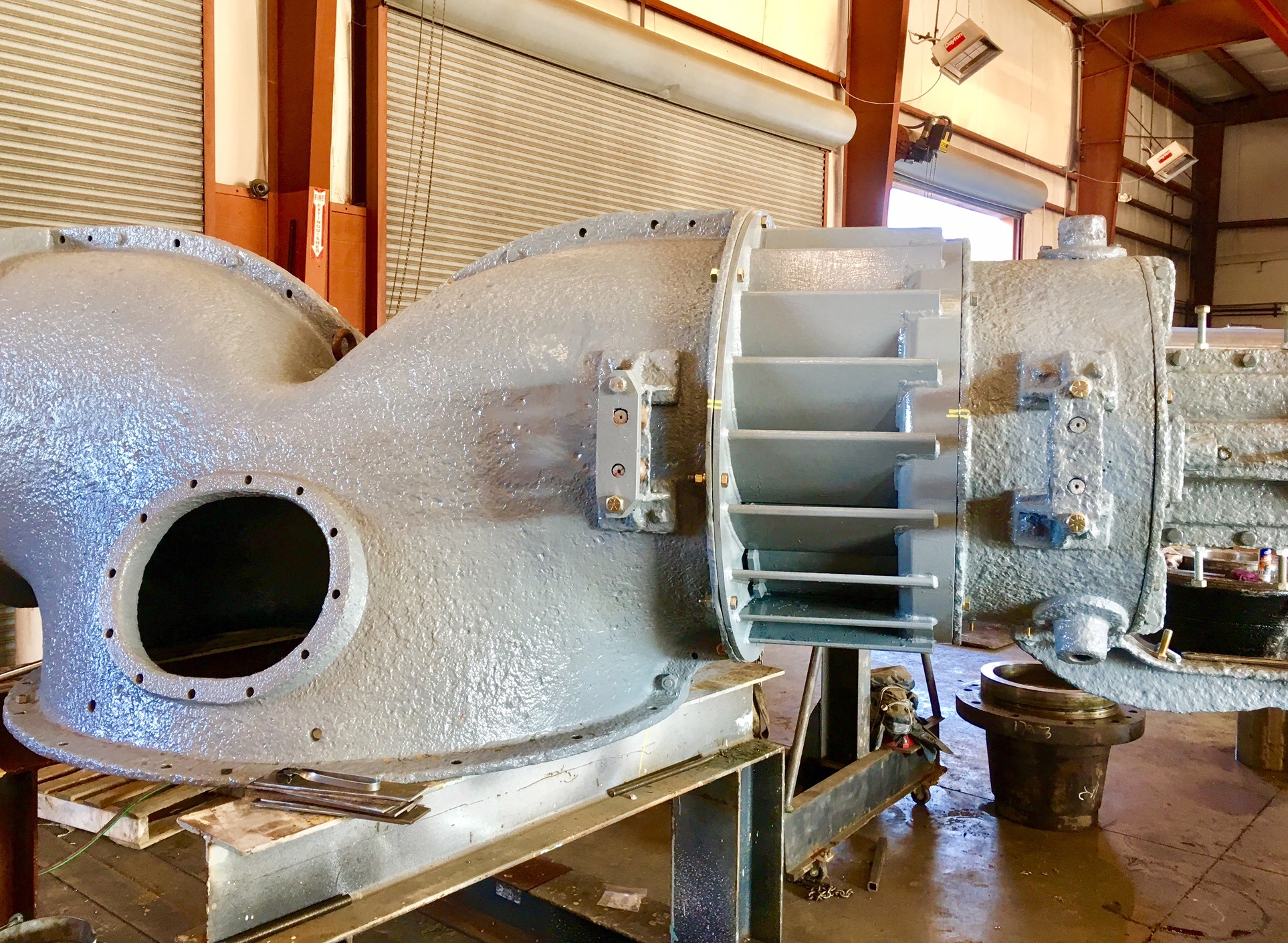

Power generation companies often need to get their mills back up and running as quickly as possible, without the added complication of waiting for back-ordered equipment. Keeping spare replacement parts on hand is not always feasible, and unscheduled purchases of new equipment can take a real hit to a capital expenditure budget. It might be time for your company to consider rebuilt equipment as an efficient and affordable option. Call RUS today to see how we can help you. Click below to view the latest brochure on our journal rebuild program.

Power generation companies often need to get their mills back up and running as quickly as possible, without the added complication of waiting for back-ordered equipment. Keeping spare replacement parts on hand is not always feasible, and unscheduled purchases of new equipment can take a real hit to a capital expenditure budget. It might be time for your company to consider rebuilt equipment as an efficient and affordable option. Call RUS today to see how we can help you. Click below to view the latest brochure on our journal rebuild program.